Thorough cleaning of the base components is essential to a quality rebuild. CrossTown uses an environmentally friendly in a shot blast cabinet, producing an O.E. level of cleanliness. CrossTown’s Lou Mangov points to a critical area: the block deck. |

The critical deck area is machined on automatic equipment, with the block indexed from the oil pan rails for consistency. CrossTown prefers to machine very close to perfect flatness to prevent close-to-limit tolerances from multiplying at assembly. |

Cylinder boring is indexed off the pan rails, and is also automated. |

Main bearing caps are machined, torqued to the block and are line-bored original outside diameter specification. |

Honing is by Sunnen CK 10. Blocks are than steam-cleaned. |

CrossTown prefers bronze valve guides for most applications. |

Heads receive valve seats as necessary and are three-angle cut using dedicated equipment. Note that the Sunnen machine indexes off the gasket mating surface. |

Valve faces are ground, and stems polished at adjacent workstations. |

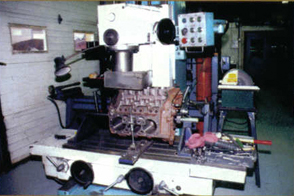

Heads receive the same cleaning treatment as blocks, and are Magna-fluxed to detect cracks. Aluminum heads are pressure tested. The milling machine uses a cubic boron nitride fly cutter to produce a very good surface finish in a single pass. |

Connecting rods are resized using this automatic machine, producing better consistency than hand-fed equipment. The box with the dial indicator at the upper left is a checking gauge. |

After all components are cleaned, assembly is performed at a central station. Engine internals other than those remanufactured in-house are new. |

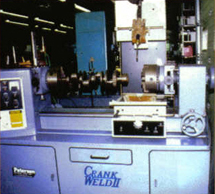

Crankshafts are ground on this Berco grinder. |

Worn journals are built up by automatic welding, then ground to original size. Mangov notes that 5.0L Ford crankshafts often show considerable wear on their thrust faces. |

After all components are cleaned, assembly is performed at a central station. Engine internals other than those remanufactured in-house are new. |

Complete engines are tested on a hydraulic machine that spins the units to 450 RPM. The test checks oil pressure and smooth operation. Note the driveshaft from the hydraulic motor to the crank on this 4.6L Ford V-8. Engines are primed, and oil falls into a large sump inside the machine. |

Jim Mangov (L), Tom Mangov, and Lou Mangov have operated CrossTown Engine Remanufacturing at the current 7500 square-foot east Toronto location since 1984. Their recommendation for no-comeback engine replacement? “Always prime the engine before startup and check the cooling system. Many engines that return are good, but have been overheated because of poor radiators or water pumps”, says Lou. CrossTown installs heat tabs to troubleshoot overheating problems. CrossTown Engine Remanufacturing is an example of a best-practices shop with good employee retention, modern equipment and careful quality control. Regardless of the source, remanufactured engines are an expensive option for consumers, making reliability very important at the installer level. For remanufactured engines, choose your supplier well. |

Blog

Our Engine Blog

Recent Comments